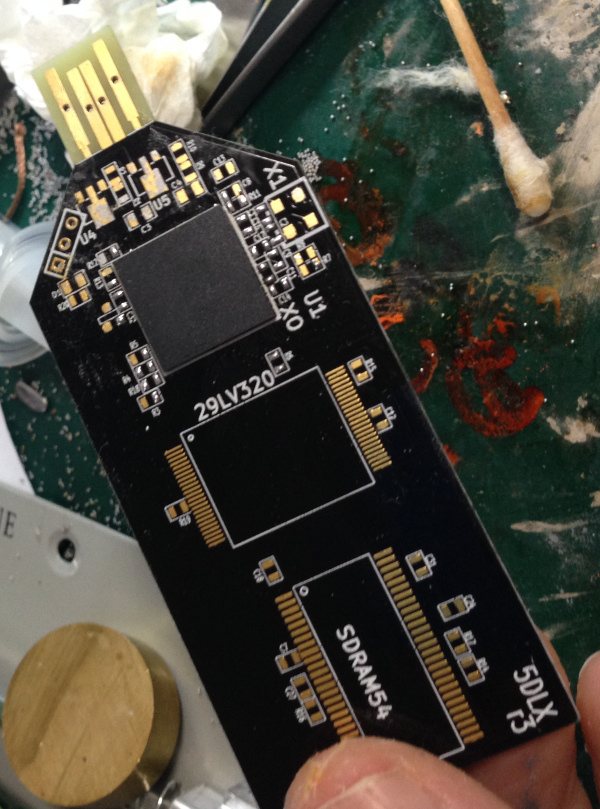

I removed the BGA part for the board, using a WEP 858D hot air rework station (flow rate 8, 350degrees). I let the part heat up for some time before applying pressure, to try and avoid pulling any pads off the chip.

I then cleaned up the part, apply a bunch of flux (any flux I had lying around, I think at this point I used goot BS-75B). Dragged a soldering iron (FX888, 350degrees) across the chip to pick up big blobs of solder.

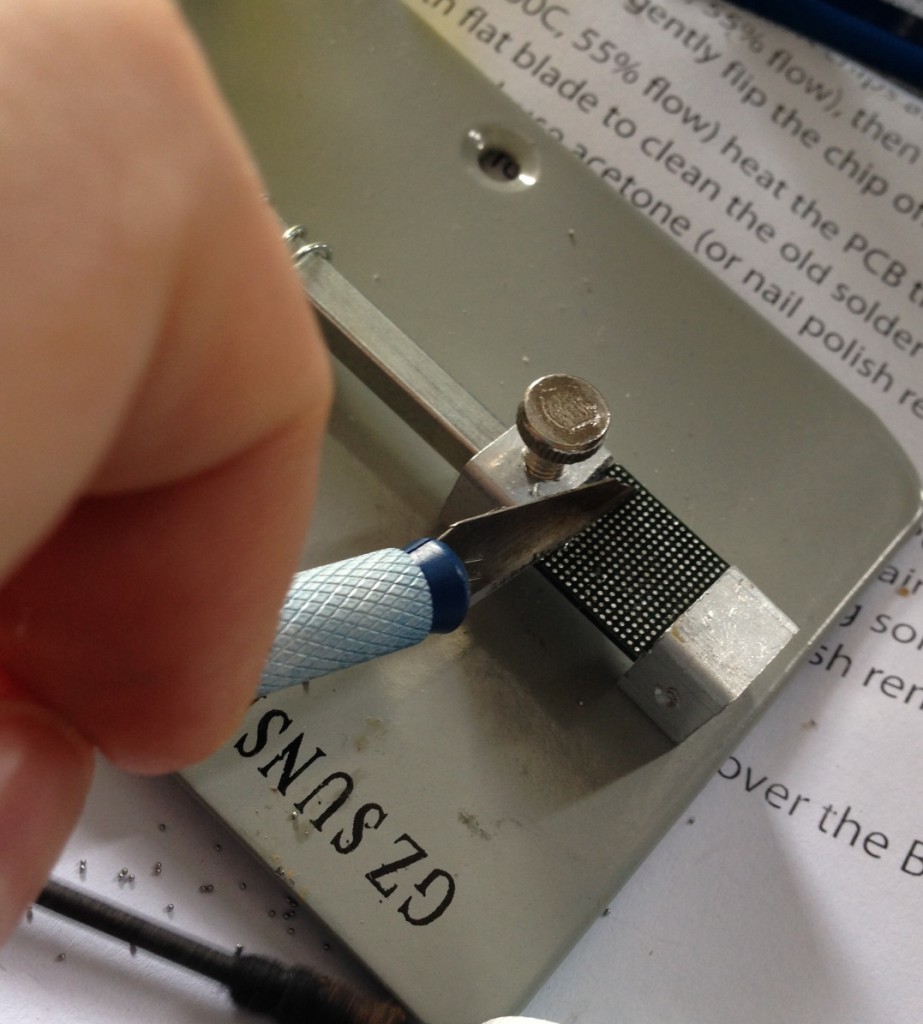

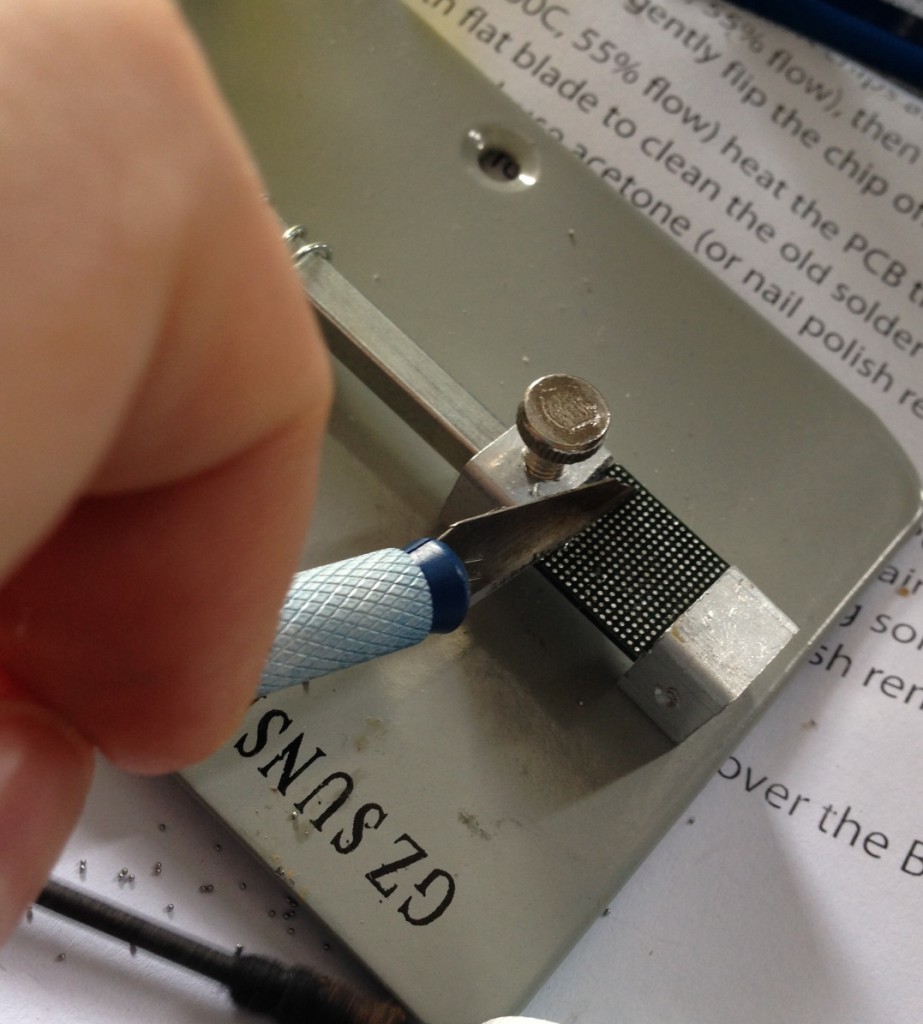

Then I set the BGA in a vice and applied heat with the hot air rework station (350degrees, flowrate 8). I gently scraped across the chip with a craft knife:

And after that went over it once more with a soldering iron. This seemed to clean things up pretty well. Though it was tempting to go over the part with some solder braid, I was concerned I’d lift pads off.

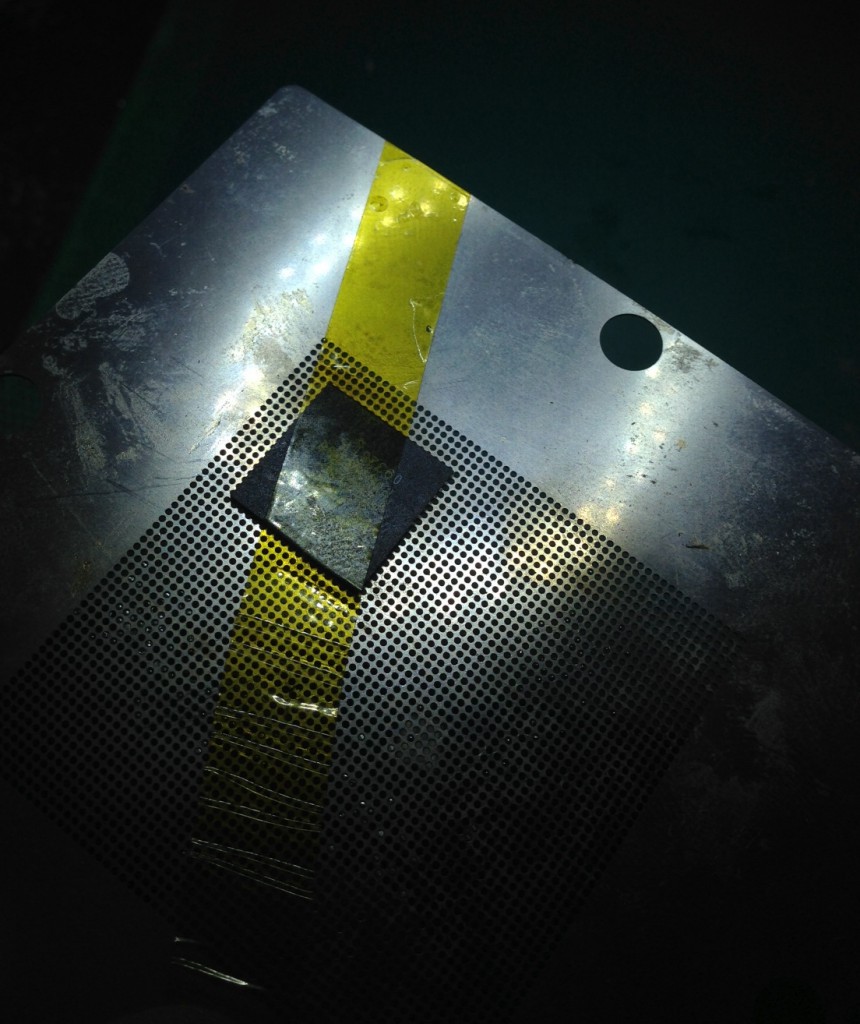

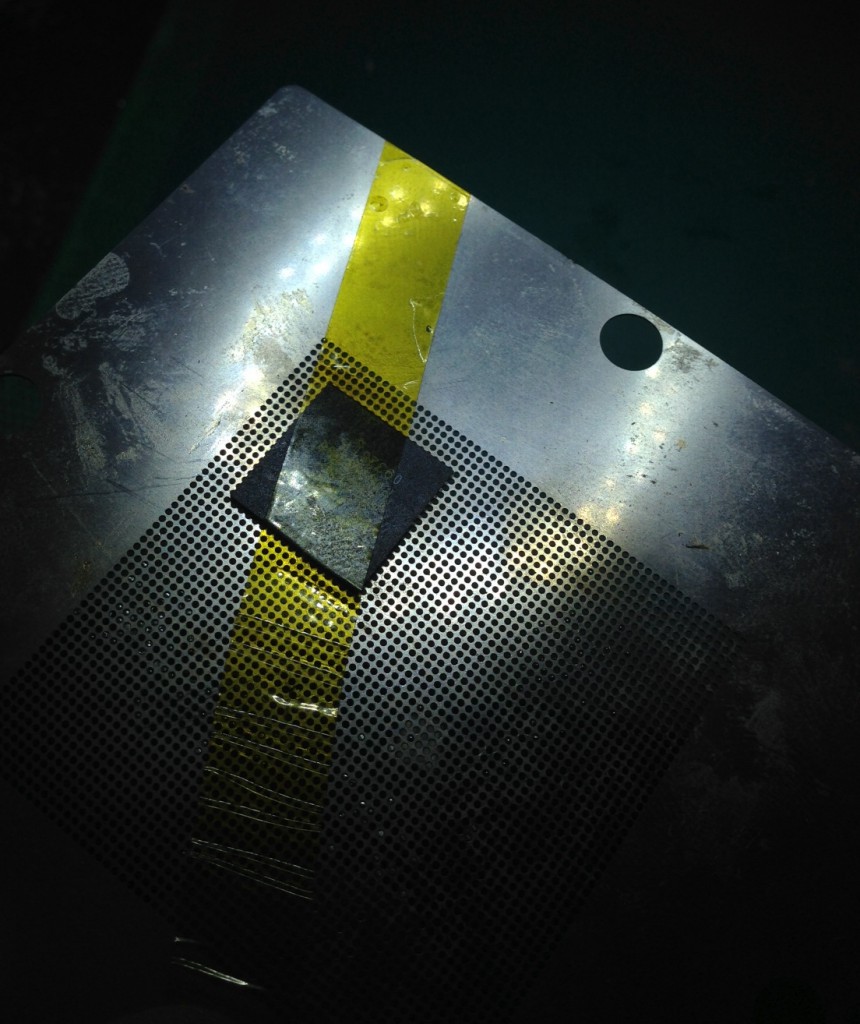

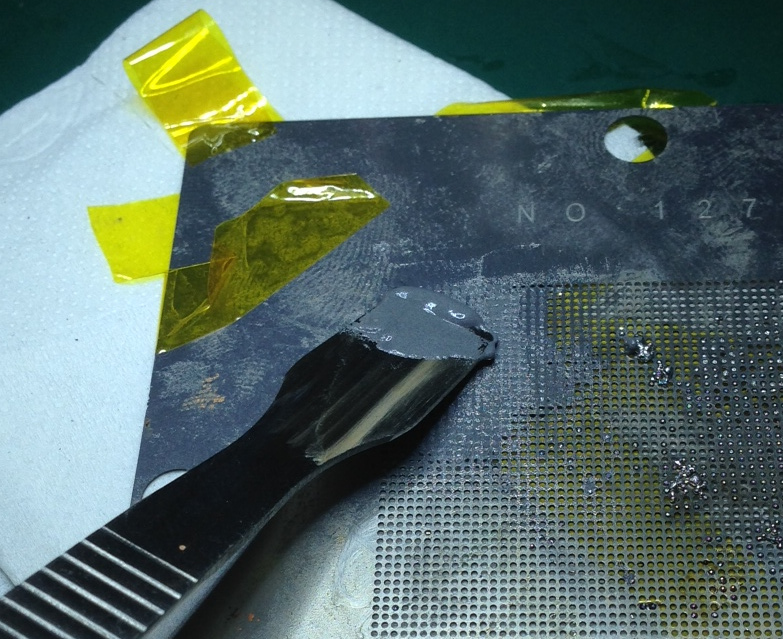

I taped the BGA part to the stencil with some off-brand kapton tape:

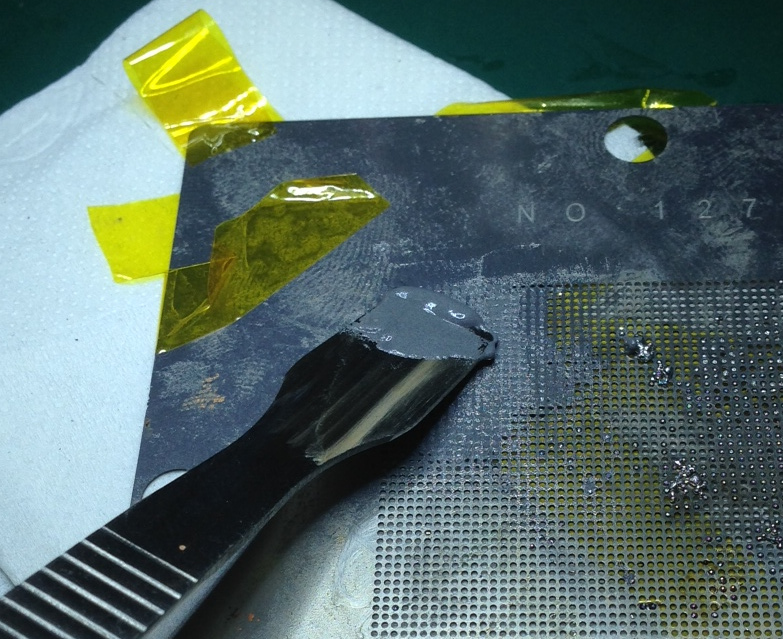

Reballing with balls – fail

BGA reballed using balls. I used 0.5mm balls (Sn63Pb37 Yue Cheng Electronics Co. Ltd). And a 0.5mm stencil. I fluxed the chip with Amtech No-clean NC-SS9 flux. As you can see this was pretty much a fail. Most of the balls just kind of stuck to stencil. They were supplied as a kit, but my guess is that actually you should use 0.45mm balls with a 0.5stencil? If you know please comment.

Update: I’ve heard from Akiba, that what a really need to do is force the balls through. I’ve ordered 0.45mm balls anyway but will try this at some point.

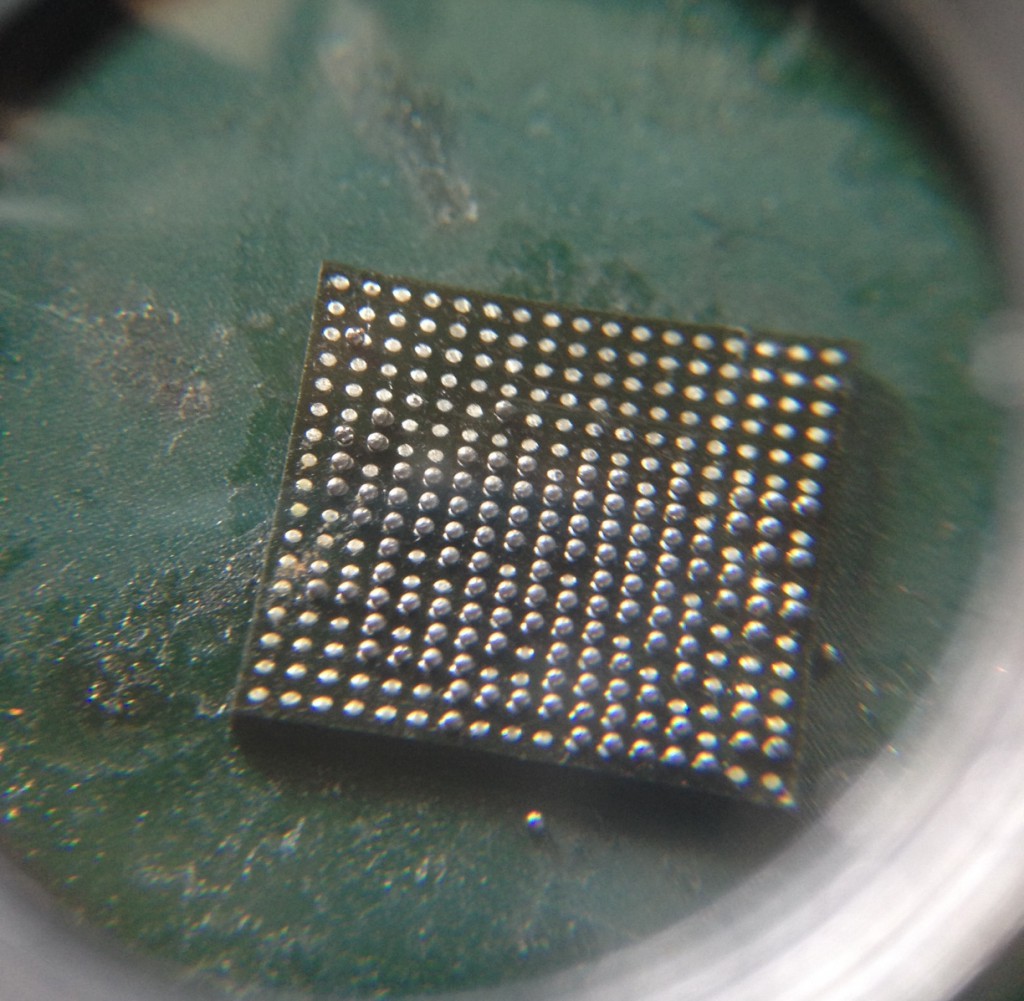

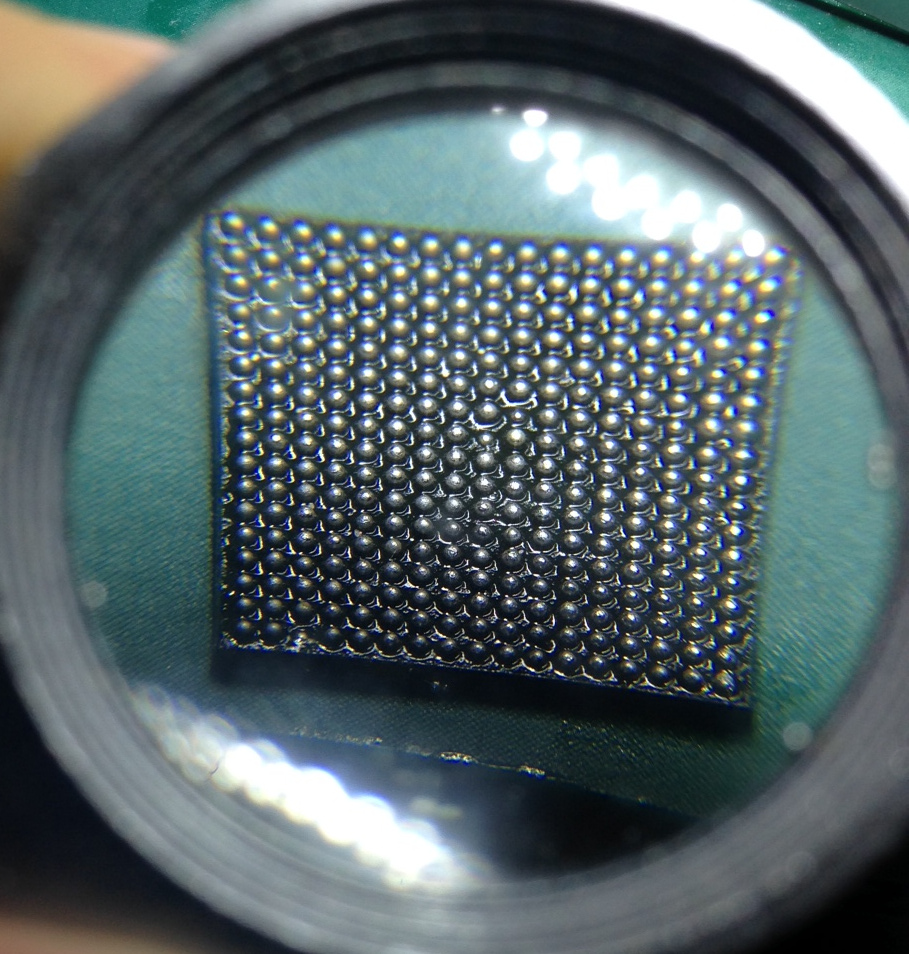

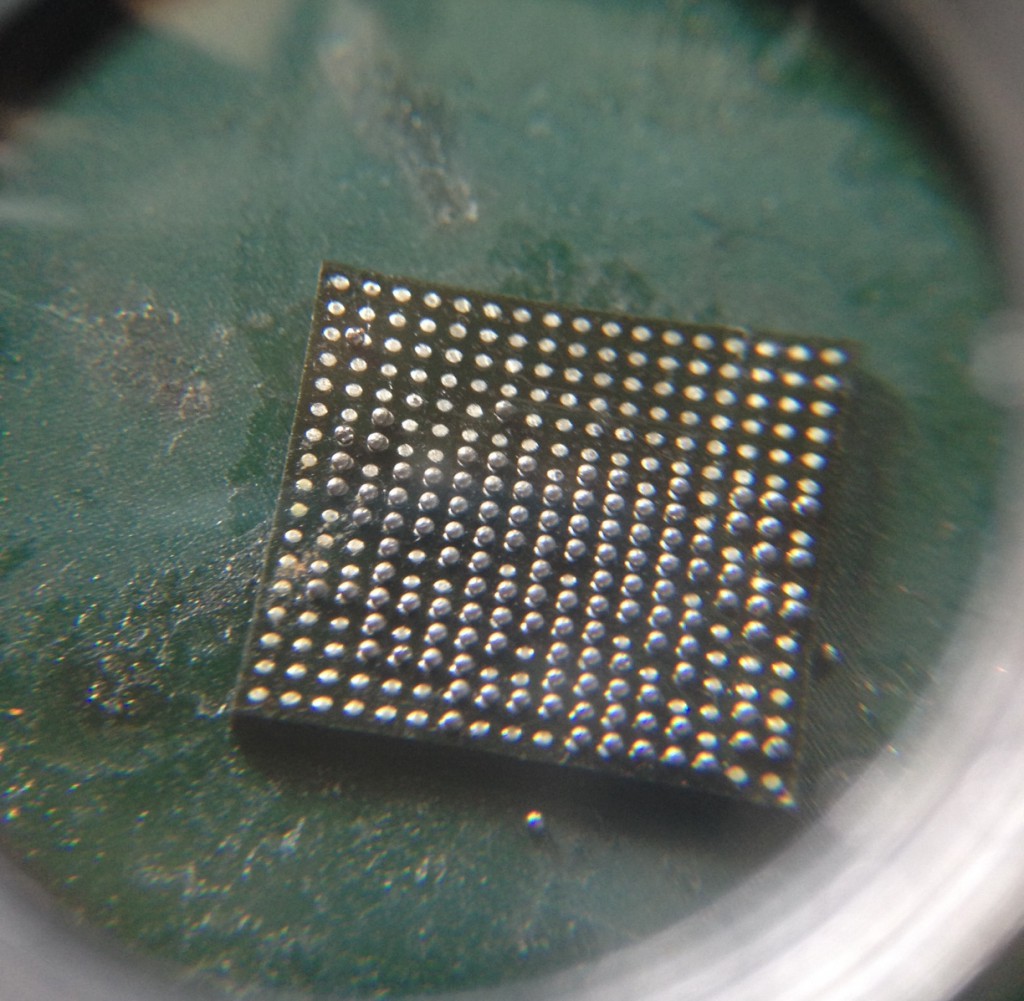

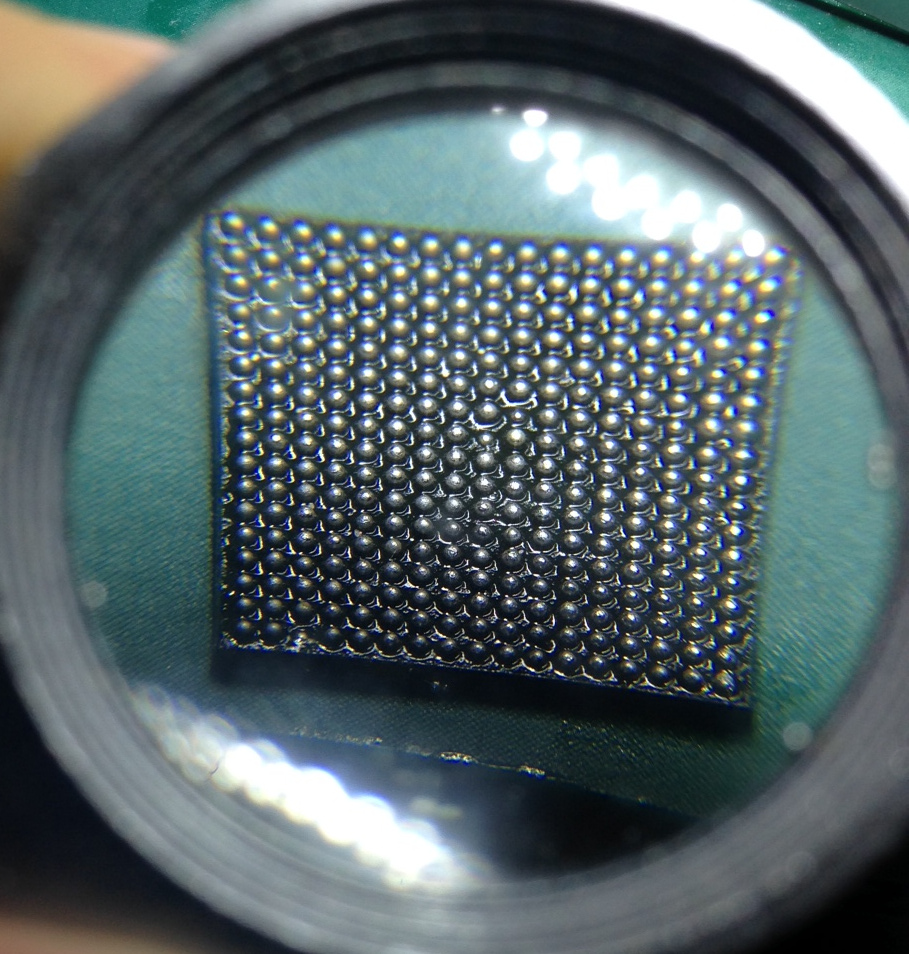

The balls that did go through looked ok:

Reballing with paste – partial success

Solder paste, the paste I have is called “Classical Mechanic Solder Paste”. XG-50 Sn63/Pb37. 25-45um.

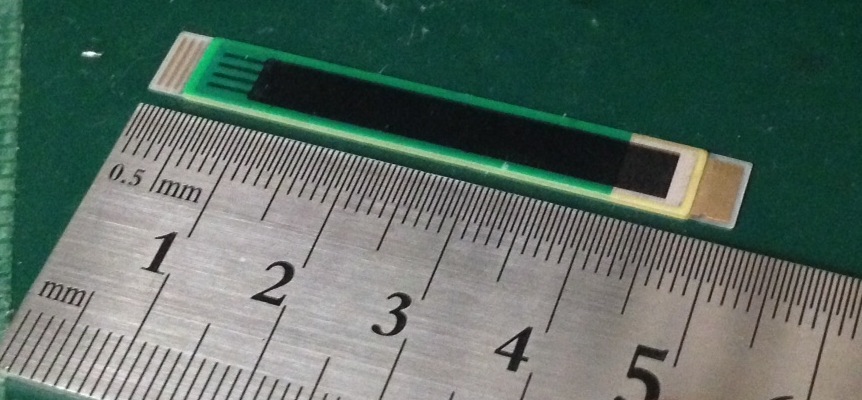

Ball made using solder paste method (I think flow rate 3.5, 200 degrees). It seems to be important to apply the flow directly downward, rather than at an angle. Also, don’t apply too much paste. Clean off excess with a Q-tip, but it’s likely excess paste will smear under the stencil anyway so you want to avoid applying too much.

As you can see a few balls are missing. Looking at the picture again, I think the ball sizes are a bit inconsistant as well. I decided to place it anyway, the unballed pins are unused, and I figured it would be interesting to try the whole process.

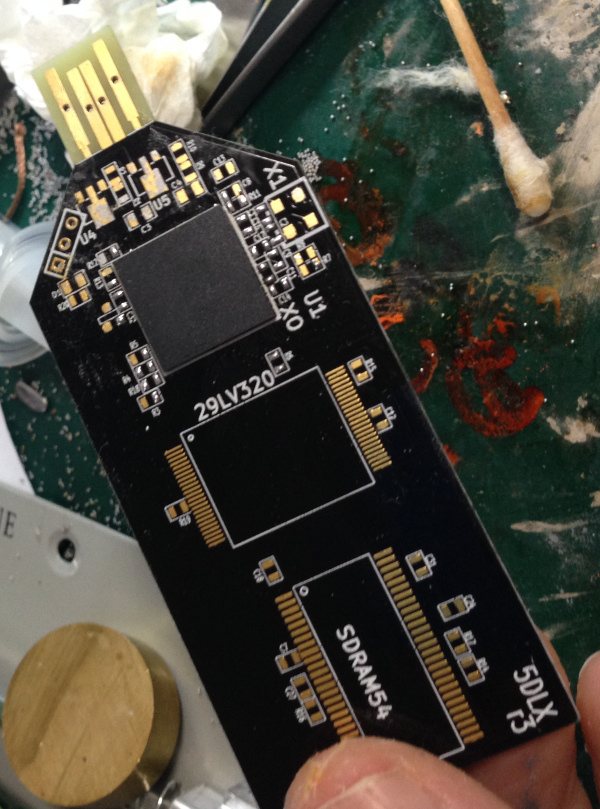

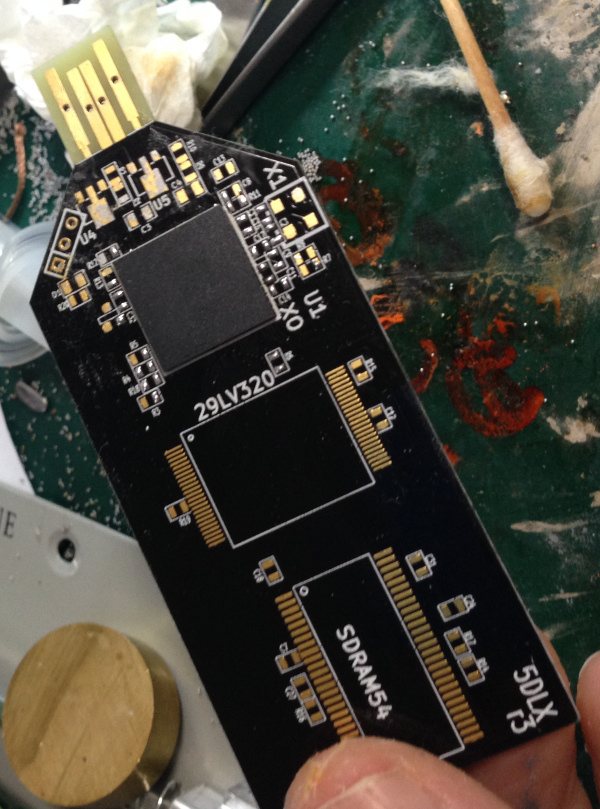

The board was plated (ENIG). I used the above AMTECH flux and spread this around with the rework station (300degrees IIRC). Then applied the above paste to tin. Cleaned with flux cleaner (goot BS-R20B), refluxed, tinned. Finally left a layer of flux on the board. Then placed the chip, spent way too much time trying to get it aligned properly.

I used a flow rate of 3.5 at 350 degrees to solder the part. I tapped the board and nudged the chip a bit which I’ve heard helps the chip align.

Everything looks good up a loupe. But I’ve yet to test it!