A short review of linear motion

This is a very short review of linear motion actuators and guides. This is I’m sure, far from complete. My hope is that people will comment and help fill out the information here.

In this post I want to address linear motion in terms of resolution, for nanoscale to millimeter scale and beyond (I know almost nothing beyond millimeter scale but would welcome contributions).

Nanoscale

I wont cover MEMS devices here, I’m rather interested in nanoscale resolution over millimeter travel. I have a short review of various piezo actuator types elsewhere.

Piezo actuators

Nanoscale resolution actuators are dominated by Piezos. Piezo electric materials directly convert electricity into motion and easily handle these kinds of tasks. In addition to this they provide high force.

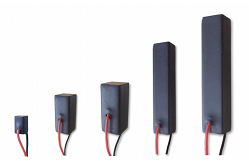

Basic stacked actuators

These devices use multiple layers of Piezo electric material connected in parallel in a stack. They provide deflection in the micron range, in general 10s to 100s of microns.

They may be combined with a mechanical advantage to increase output force.

Inchworm actuators

Inchworms use piezo stacks to push a rod along. In this way they retain their nanoscale resolution, but vastly extend the travel of the system. Inchworms with 25mm travel and beyond are available and can be purchased for a few hundred dollars.

LEGS actuators

I strongly recommend you check out the video linked above, it’s awesome. LEGS (R) is a trademark of Piezomotor (R) I believe. They use a slightly different mechanism to the normal Inchworm, using bimorphic benders to walk along a shaft. Similarly with microstepping they can achieve nanometer resolution, and millimeters of travel.

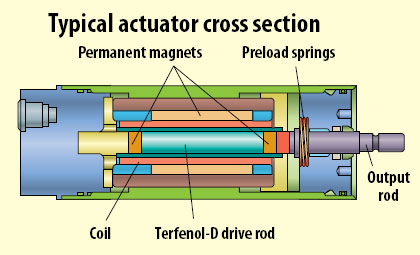

Magnetostrictive actuators

Magnetostrictive actuators have recently begun viable for nanoscale linear motion. These actuators use magnetostrictive materials (notably Terfenol-D) which when exposed to a magnetic field, change shape.

While nanometer precision can be achieved, magnetostrictive actuators exhibit hysteresis and non-linearity. While this issues are also present in stacked Piezo actuators they are mitigated against in Inchworm and LEGs actuators.

Electrostatic actuators

A far am I’m aware these have never been used commercially, but have been proposed as academic research tools.

Micron scale

Nanoscale actuators are dominated by DC driven Piezos largely because of their inherent precision and low vibration characteristics. Once we reach the micron scale things get much easier as we can begin to use motors again. A typical low force application at this scale would be a motorized microscope stage.

Vibration characteristics are again a concern here, and will need to be considered carefully.

Coreless DC motors

Coreless DC motors, coupled with a leadscrew are often employed for micron scale actuation. Unlike normal motors coreless motors have no Iron core to confirm the magnetic field. This lack of a core allows the magnetic field to be built up and broken down much more quickly resulting in faster and more precise acceleration. Chuo Seiki sell these with gearing and a leadscrew in a micrometer style configuration, and they often appear to be used as “motorised micrometers”.

I have a used Chuo Seiki actuator on order and will update here when it appears.

Steppers

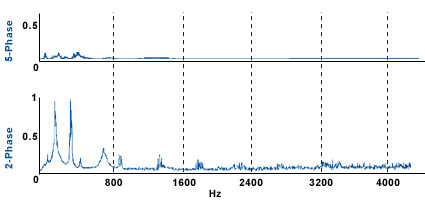

Stepper motors are also employed for micron scale resolution actuation. In particular 5-phase steppers are favored here. oriental motors have a great write-up on why 5-phase motors are better, but overall it comes down to their reduced vibration:

They should of course also be operated in microstepping mode. Oriental motors appear to supply the majority of 5-phase steppers for micron resolution actuation. Again this are commonly employed for use as XYZ microscope stages or semiconductor fab applications. When coupled with a leadscrew and rail guides, micron resolution can be achieved. An example is again the Chuo Seiki stage. I have again purchased one of these second hand and will be updating with my experiences here.

Micron resolution can also be achieved here with 2-phase steppers, as can be seen in commodity electronics such as DVD players where the track spacing is on the order of 1micron. However the accuracy is likely low.

Millimeter scale and beyond

Steppers

At the millimeter scale (~100micron) things appear to be much easier and commodity 2-phase steppers coupled with a linear guide and lead screw are generally employed. Of course in commodity electrics belt driven systems as also used.

Servos

Servos have a number of advantages, in particular for CNC applications. Servos are able to operate at higher speeds. Because of their inherent feedback there is little potential for “missed steps”. And as servos do not operate a step at a time, their vibrational characteristics are different (and generally better) than those of steppers.