A Note on Collaborations

This note is on collaborations where some overlap exists between technical development, artistic elements, and user requirements. The focus is on hardware collaborations, where no money changes hands. These notes reflect my personal experience, and observations of collaborations to date.

The first point, is that if you have a strong desire to complete the project rather than engage in open ended discussions it’s important to get explicit agreement from individuals engaged in the collaboration, and on any external deadlines.

Implicitly, it will be up to the individual who proposes the collaboration to manage the project. The ideal scenario is if a single individual can create the initial proof of concept (others offer advice, suggest easy to use parts).

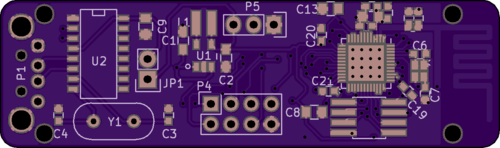

Hardware collaborations generally in my experience take at least 3 revisions to get to a reasonable proof of concept.

In most cases you should budget at least a month per iteration, regardless of complexity. This is because unless you are funded you’ll be acquiring PCBs and other parts from China (this is x5 to x10 cheaper). Shipping these parts takes on average a month.

Specific Guidance

Early in a project, it’s useful to get answers to specific questions, these vary depending on the project, but where appropriate it’s useful to get answer to the following.

General Questions

- Are there any deadlines involved (for grants etc)?

- What environment will the project be in (indoors? Outdoors? Vacuum?)

- What is the power source (battery, mains)?

Sensor projects

- What are you measuring?

- With what accuracy/resolution?

- How long will the sensor be acquiring data unattended?

- Where is data stored? Or how is it transmitted?

- Data visualization requirements?

Motion projects

- With what resolution/accuracy do you need to move the actuator? (nm,um,mm,cm?)

- Over what distance do you need to move the actuator (um,mm,cm)?

- Linear motion? Rotation?

- If possible, provide a sketch of the system, with approximate dimensions.

- If moving a static load, what weight does the actuator need to move?

Imaging projects

- If optical imaging, what wavelengths are you interested in (visible light only?)?

- Resolution,accuracy,noise levels, quantum efficiency requirements?

- Will image stitching or computational intensive post-processing be required Do you have access to compute?

- Do you have access to adequate image hosting facilities?